A MODULAR SHINGLE SYSTEM

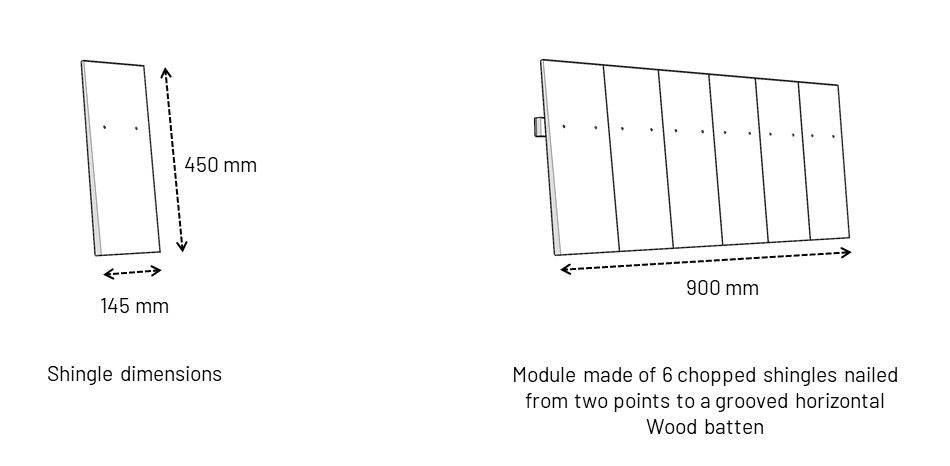

Shingle details

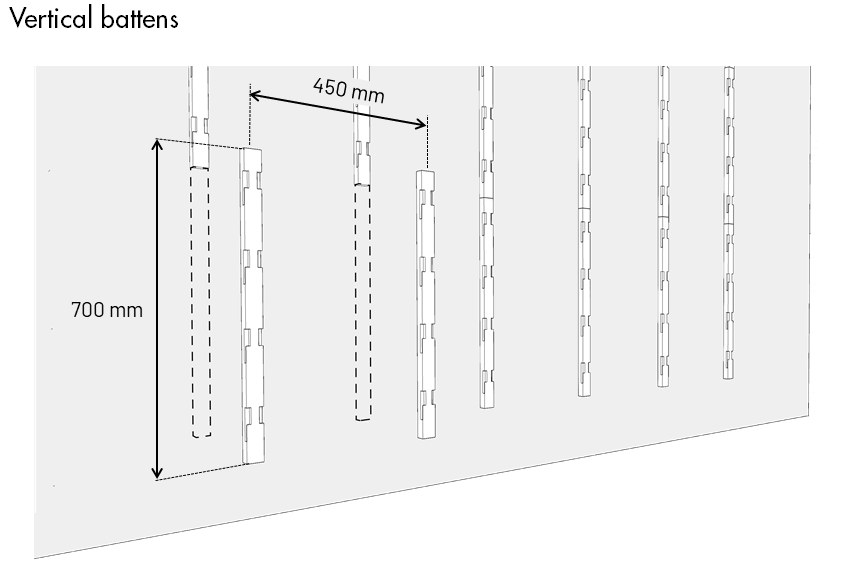

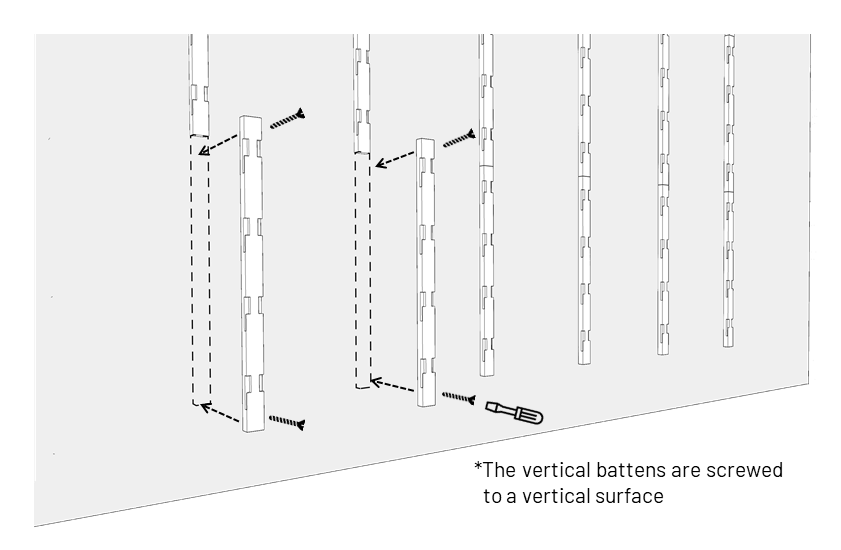

BATTEN STRUCTURE

FASTENING DETAIL

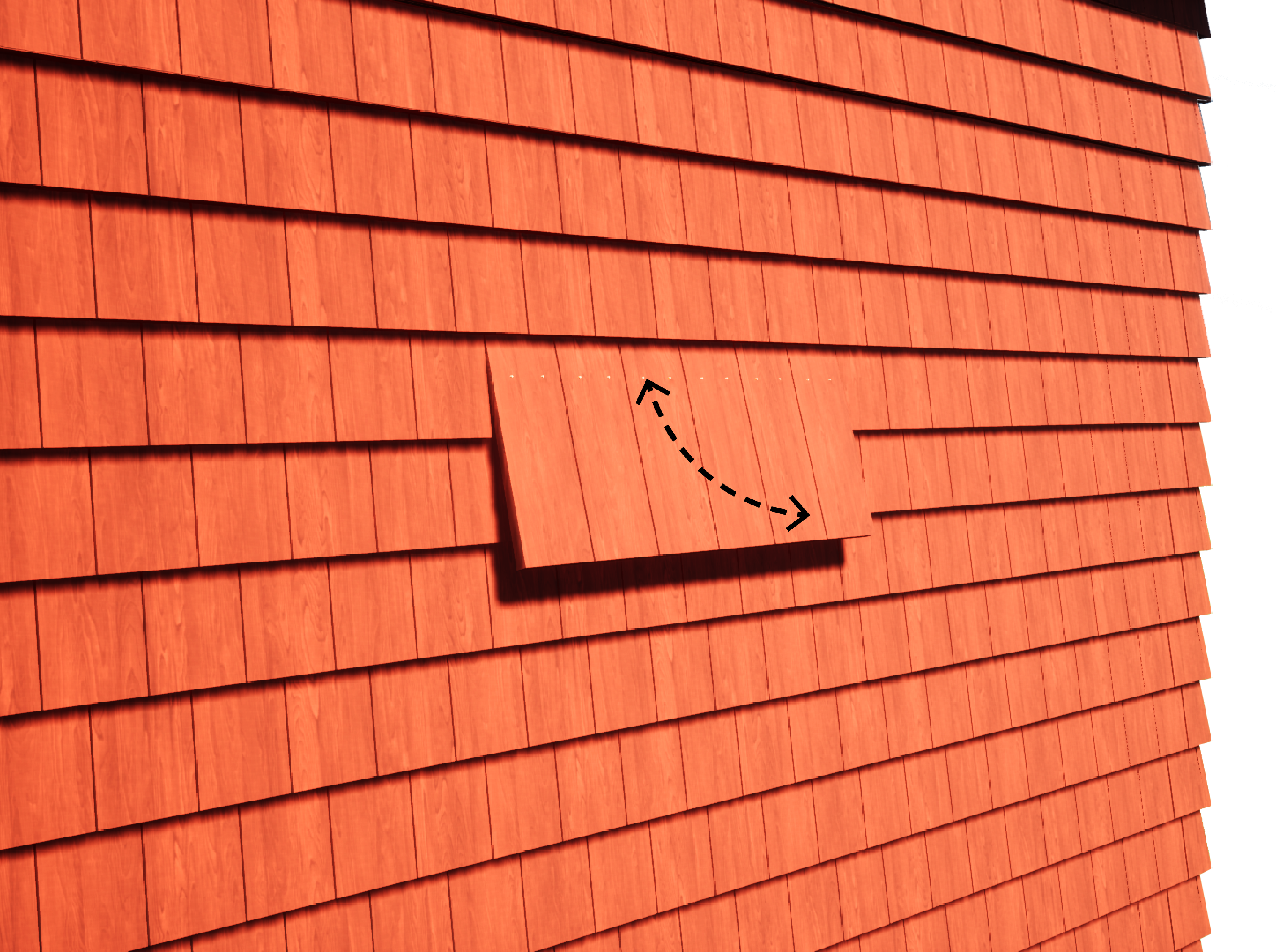

The fastening between the vertical and the horizontal battens is made with a set of tongues and grooves. The aim was to make a simple detachable system for having a non-destructive removal process, where most of the cladding pieces could be reclaimed (click on top of the image to have a closer look).

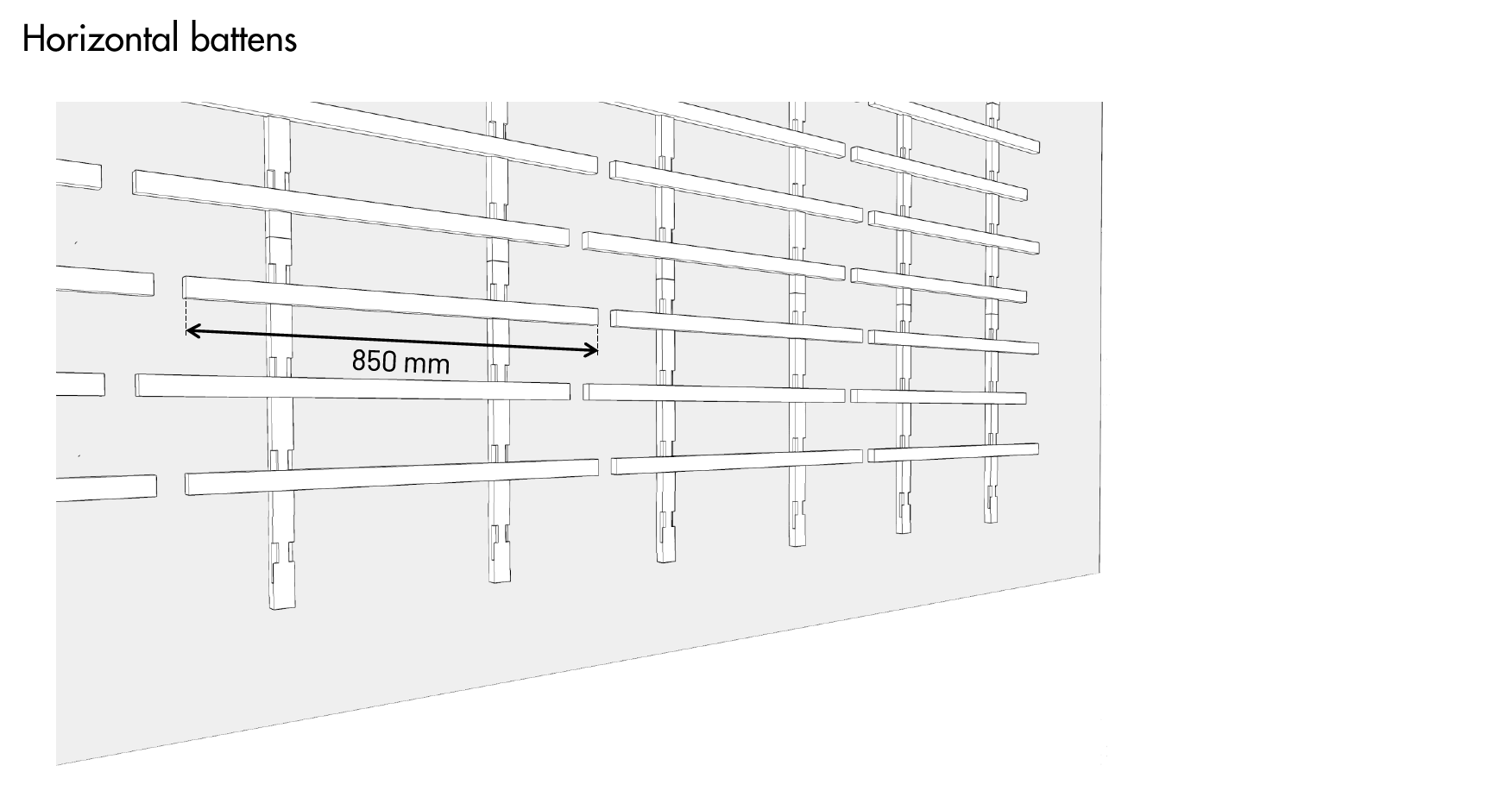

This image sumarizes the project in a way that it shows from left to right, the wood treatment, the wood selection and the design of the shape of the cladding.