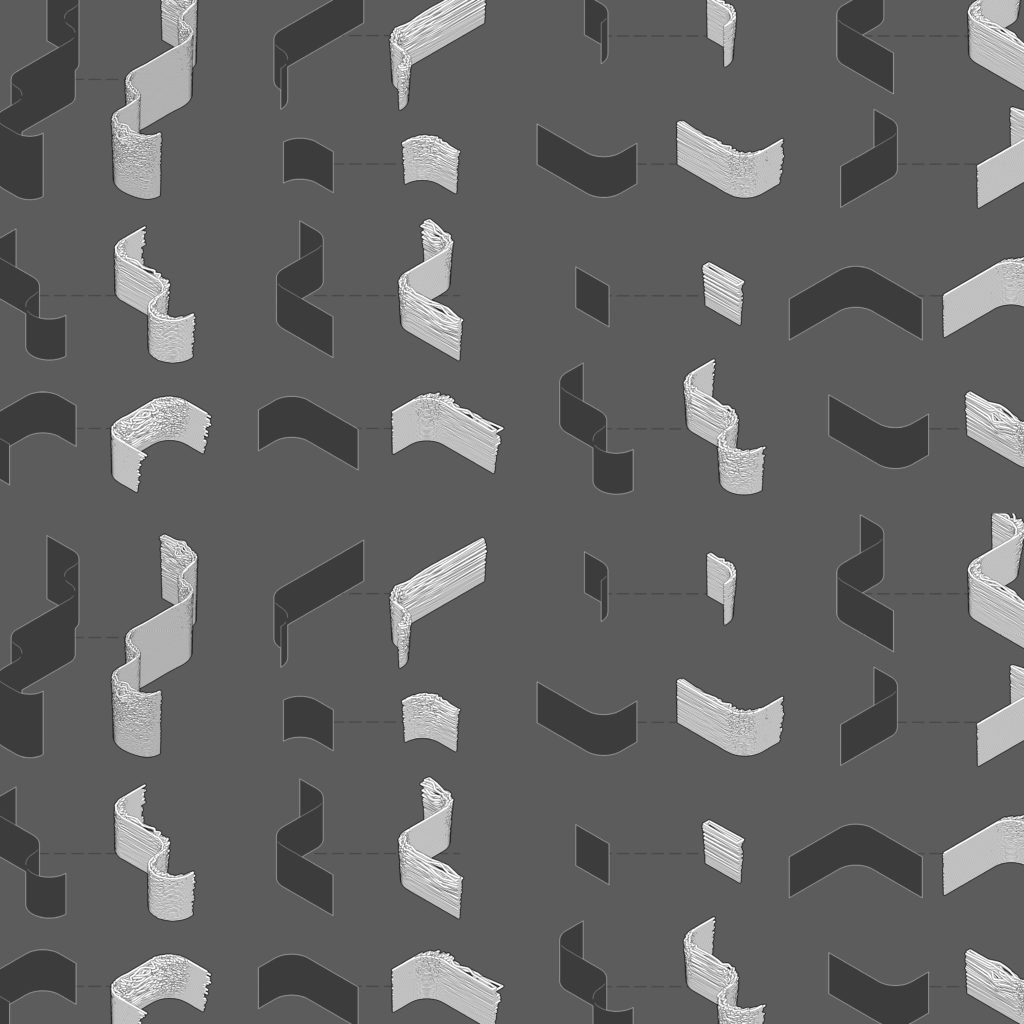

So far, through sets of explorations and ideas, the surface has become almost insignificant to the resulting artifact. How these surfaces are interpreted by the 3D printer becomes the major part of the design. So how can one rationalise these surfaces in a large scale structure?

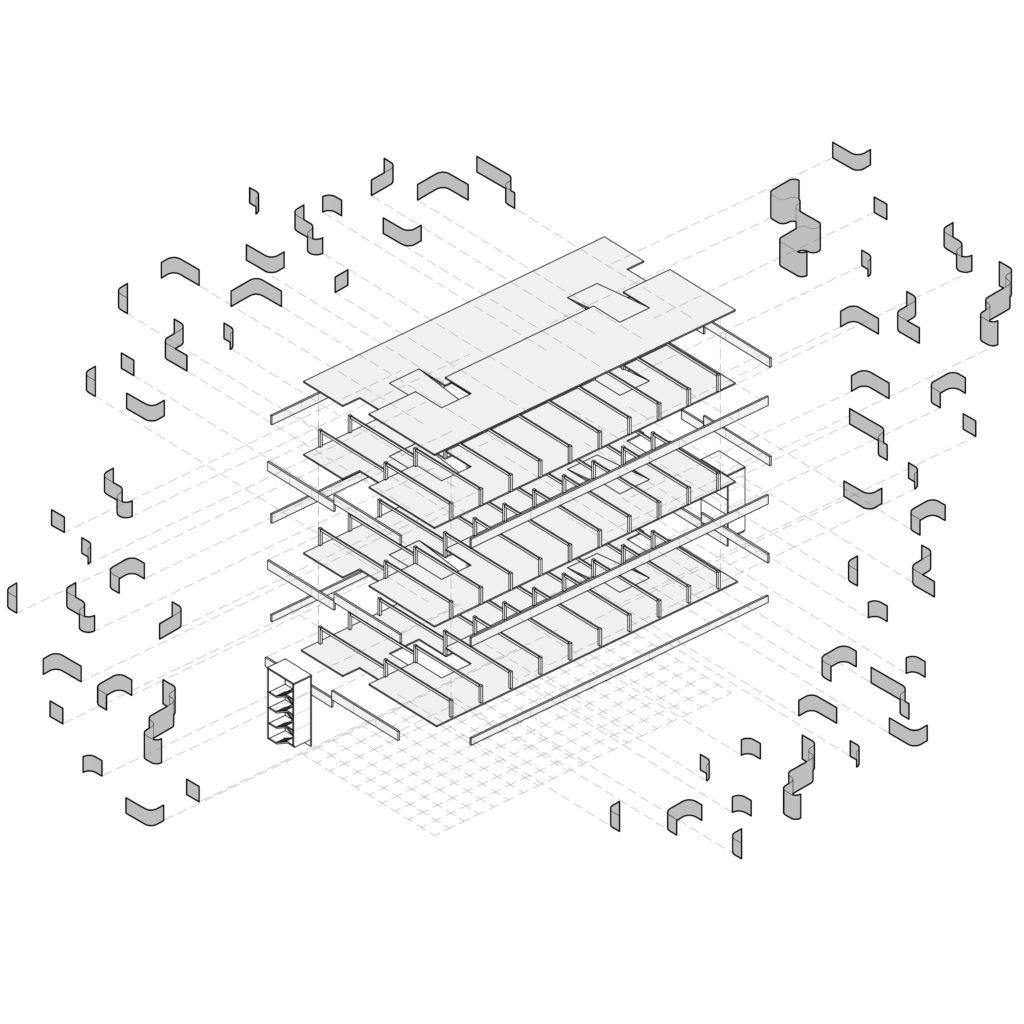

Existing building elements were to be introduced into my explored fabrication methods. With many demolitions of the over 1000 carparks in Singapore taking place, it would be proposed that new structures were to be built in its place.

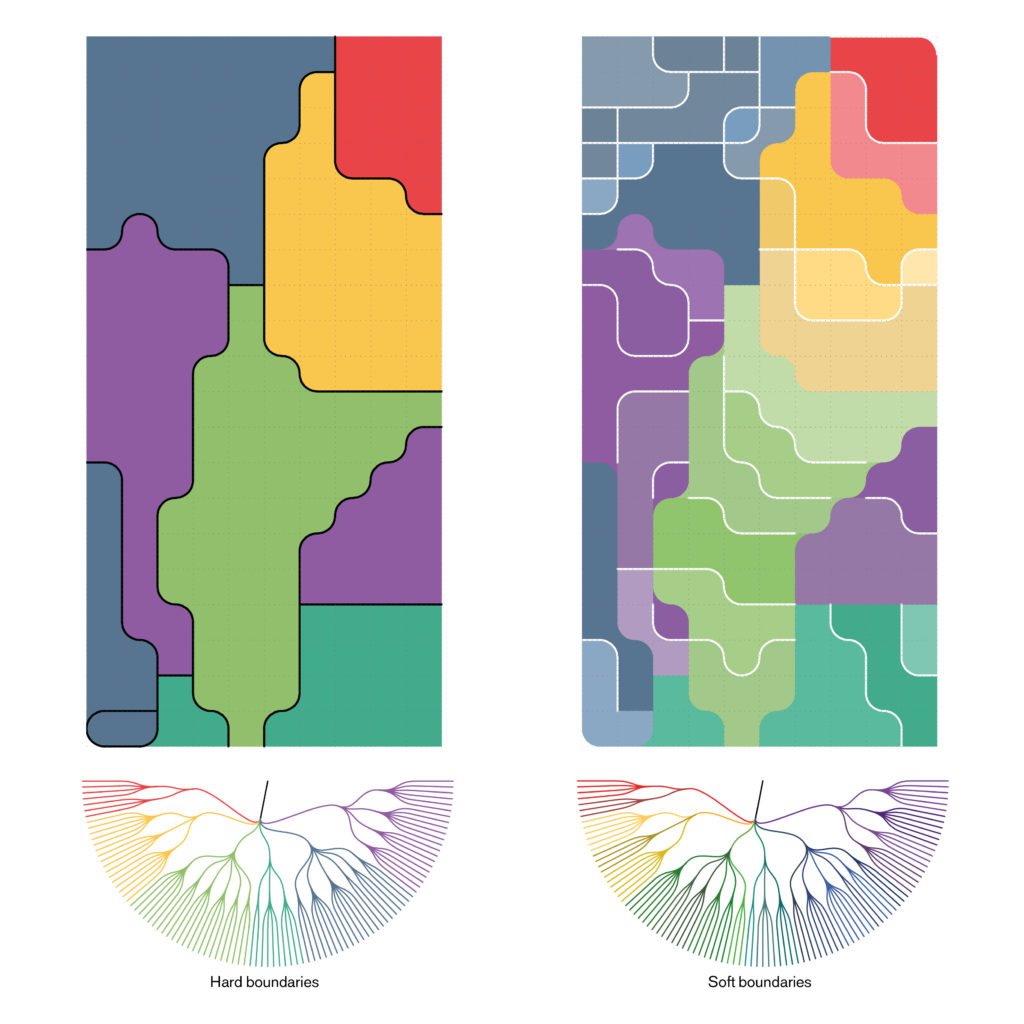

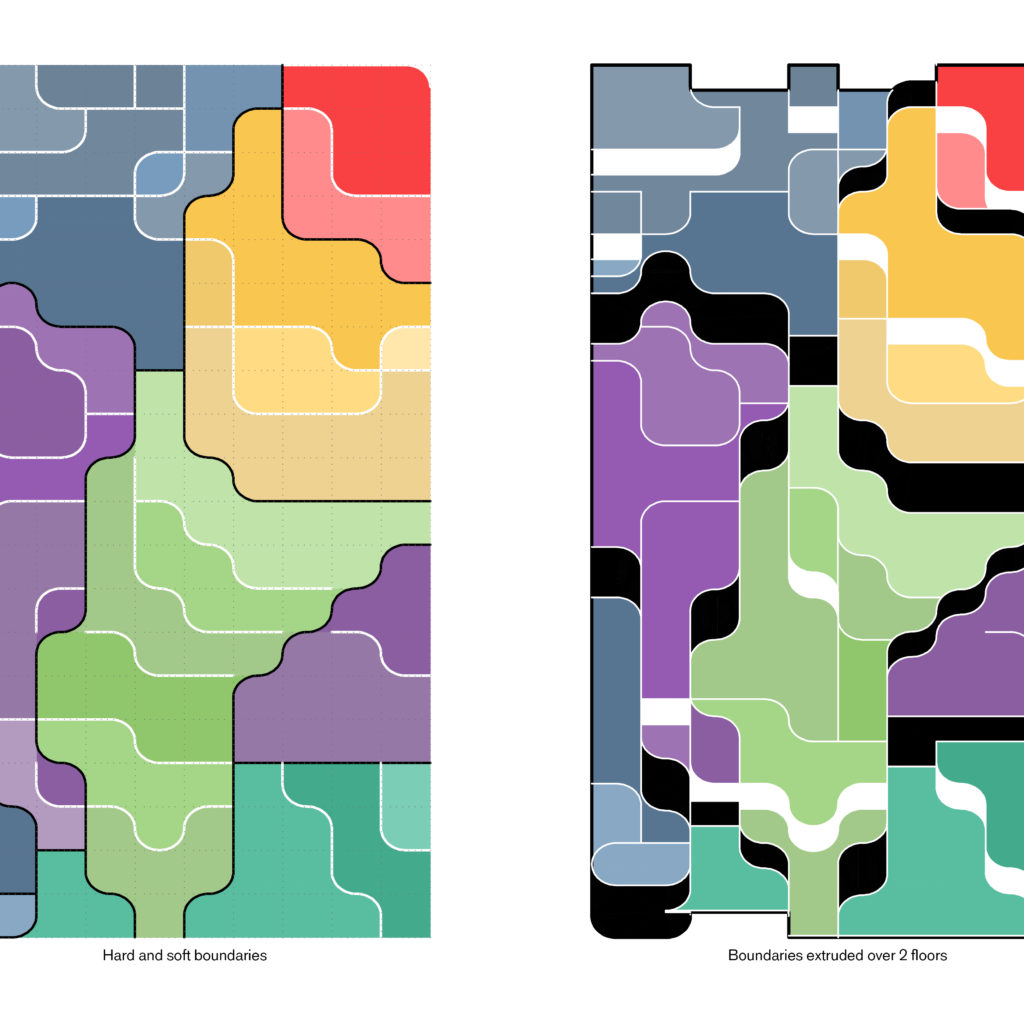

These structures were to reinvent the courtyard into dense outdoor lightyards, reflecting the complex nature of family structures. By analysing existing family trees, hard boundaries were established that divided spaces at the grand parent level where individual families created a gradient of softer boundaries

Spread over 2 floors, the hard boundaries are extruded over the extent of the floors whereas the soft boundaries are extruded over a single storey:

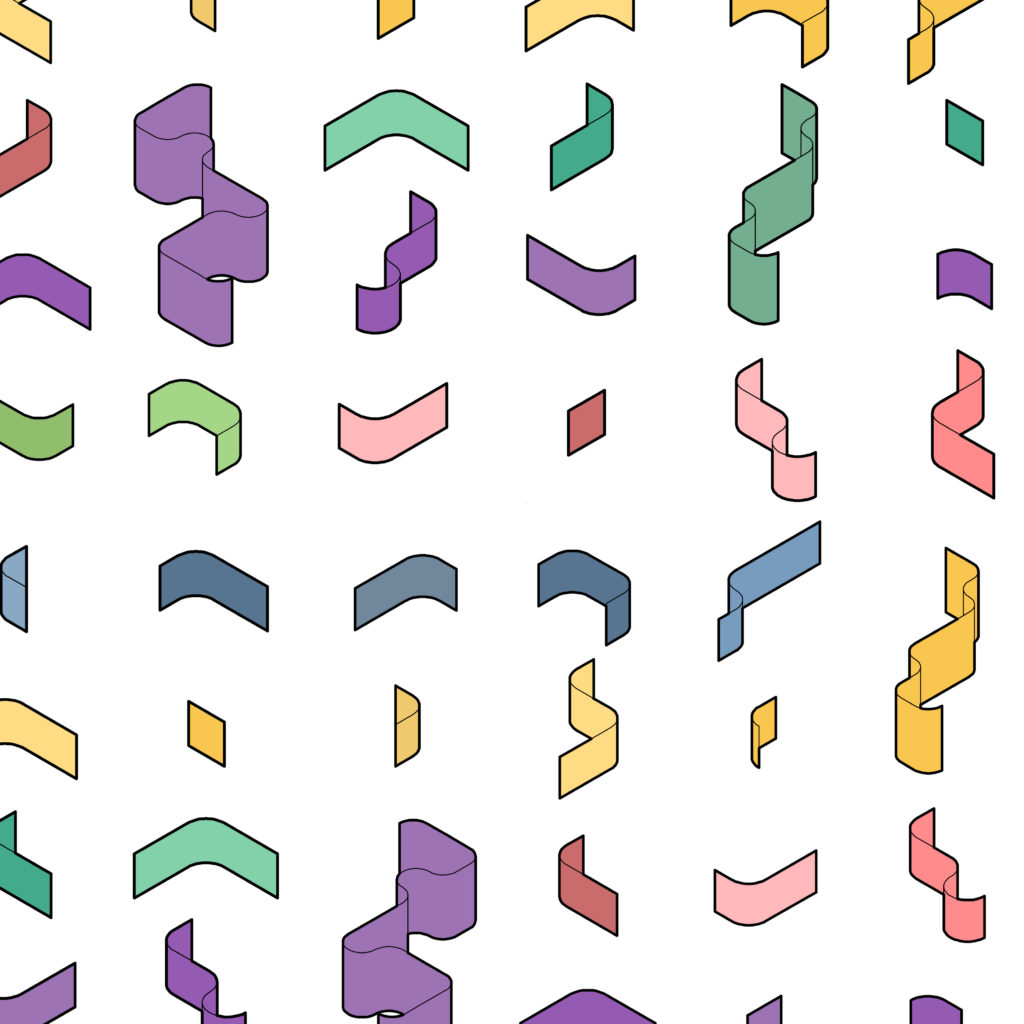

The boundaries become a catalogue of surfaces that can be translated by the jittering of the 3D printer. Typically, as designers, we give the 3D printer as much information as possible, 3D modelling models as detailed as we can. Here, the 3D printer is given vague surfaces where it becomes part of the design process where it can detail the surfaces itself.

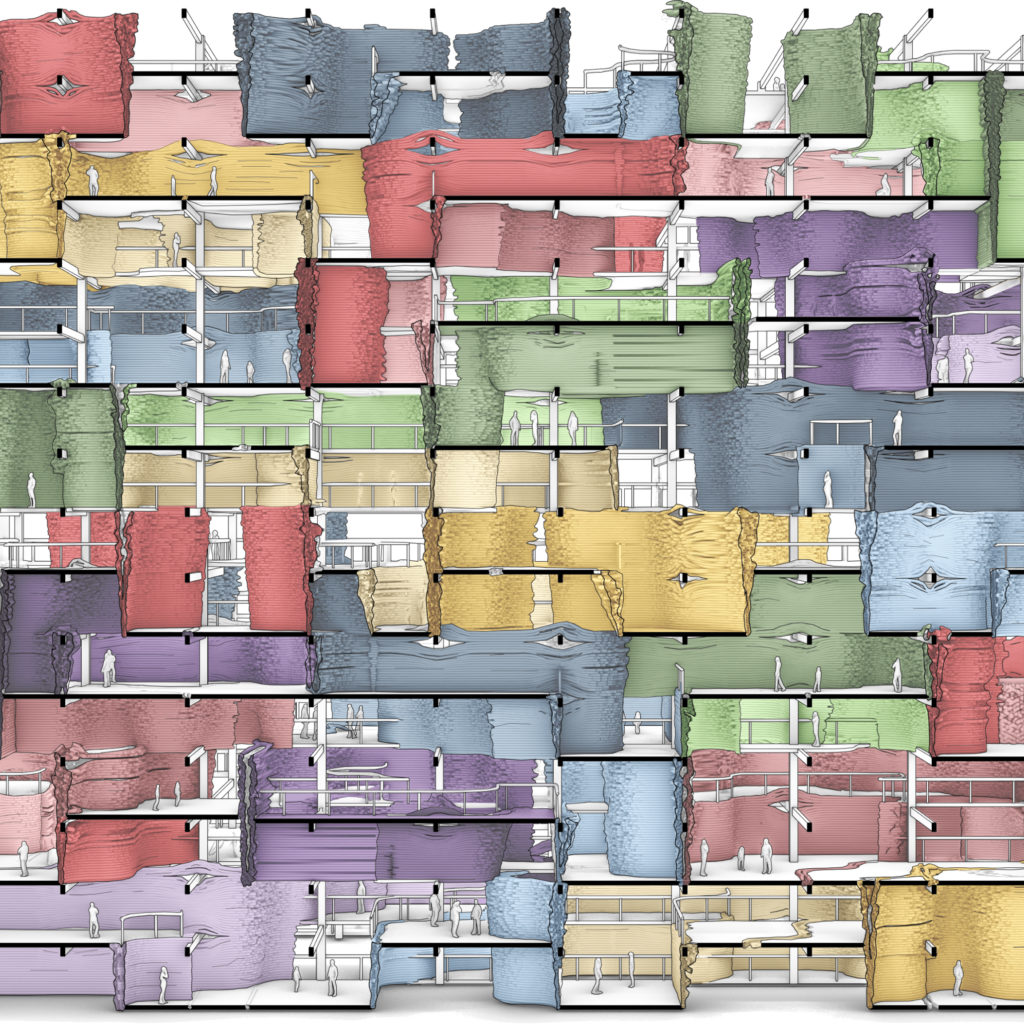

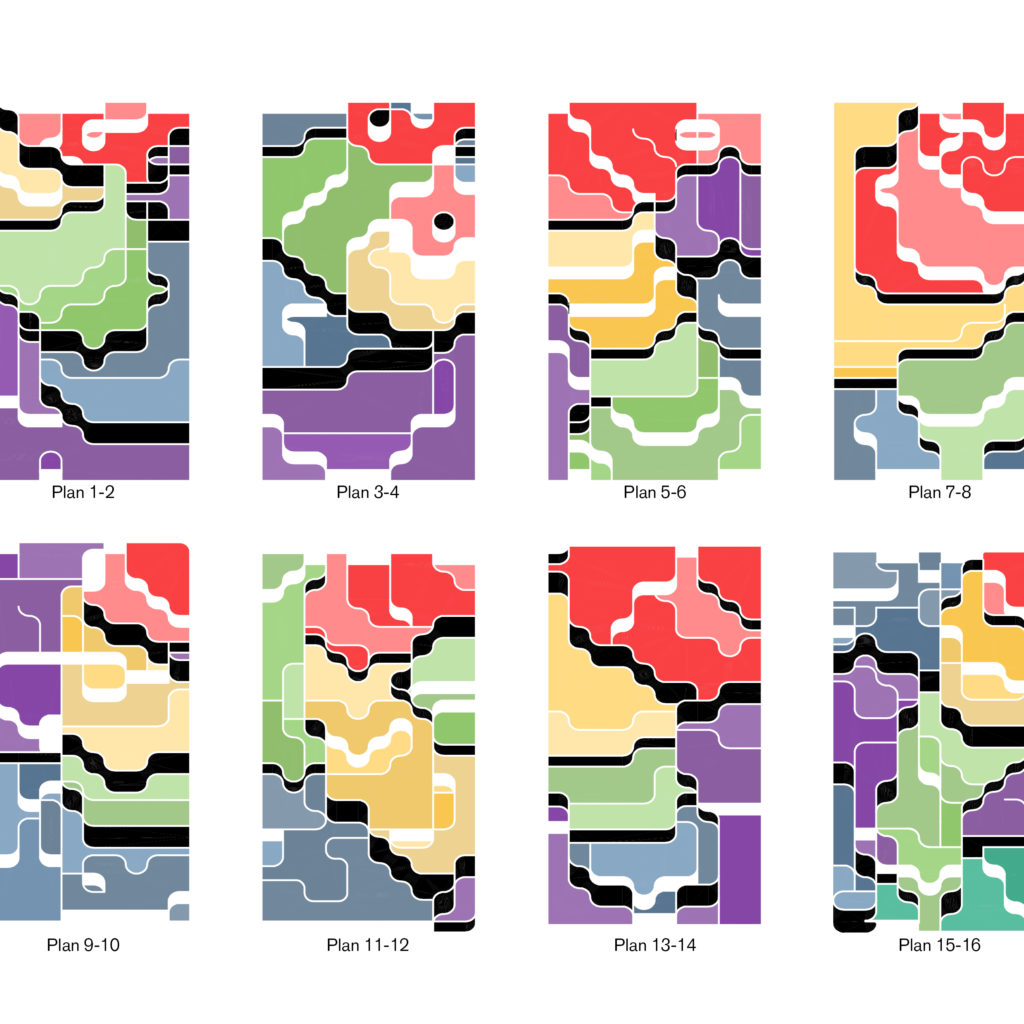

Analysing several more family structures give more data / surfaces that when stacked together…

become a large open air structure, bringing in light from various apertures. Despite the autonomous nature of its creation, the structure feels unplanned and scattered. This interplay between chaos and order is possible only through the parameters and rationalisation of data.