Towards the industrial reuse process

BY Amilia Björklund & Maja Lindborg

Information management

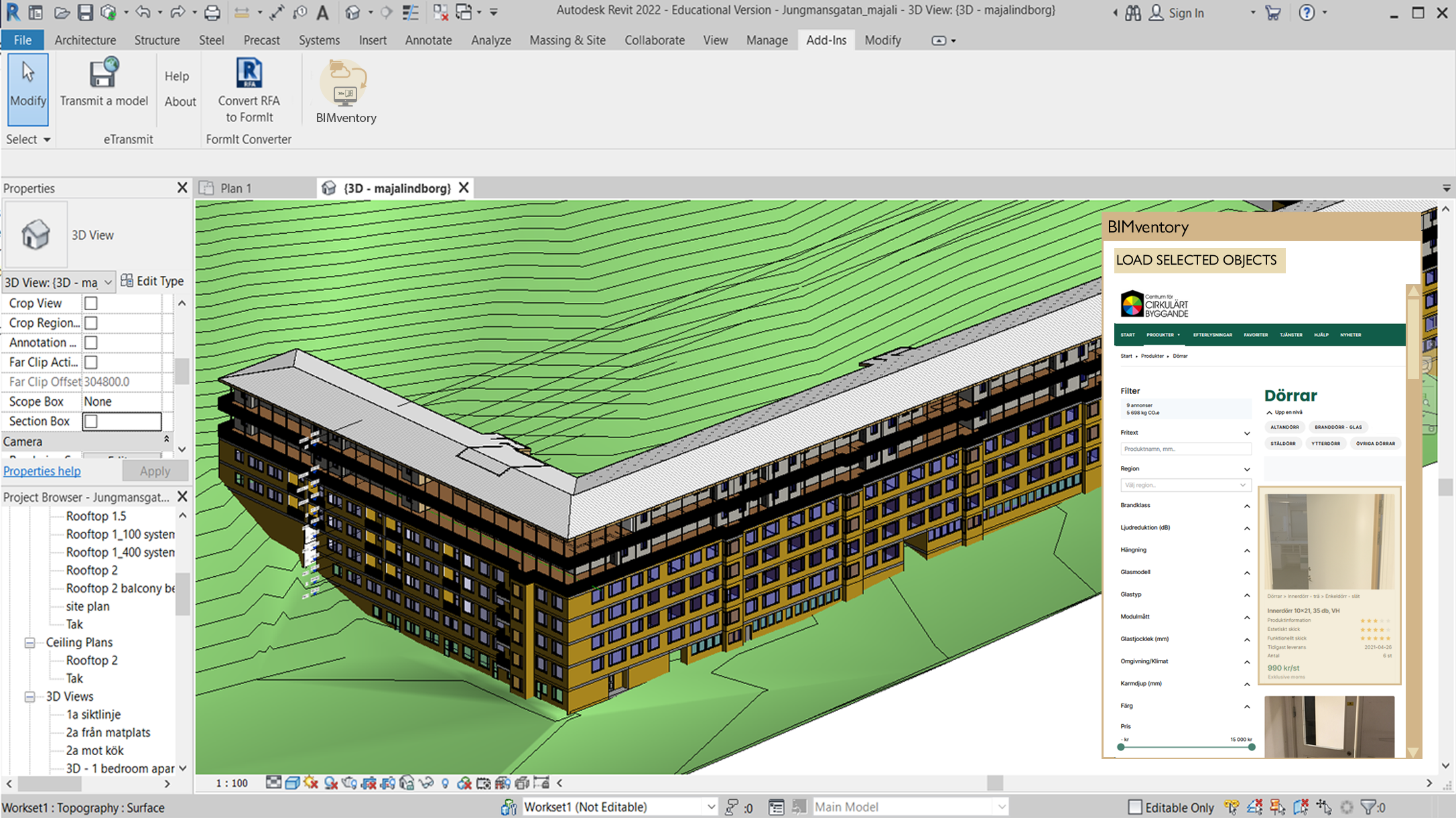

To be able to import the inventory data from the reuse database and generate BIM objects, a concept toolchain was developed to describe the development of such a function, along with a workflow on how it would be used by the designer. The main idea of the toolchain is to provide a communication platform between the reuse database and the BIM model.

PREREQUISITE.

Upload information to the existing reuse database, based on inventories.

STEP 1. SYNC WITH THE REUSE DATABASE.

Filter what type of reused building parts you want to integrate in your design, and download the object information from the existing reuse database to your BIM model. These building parts then gets ‘reserved’ for 48 hours to prevent other users from downloading them. (API in)

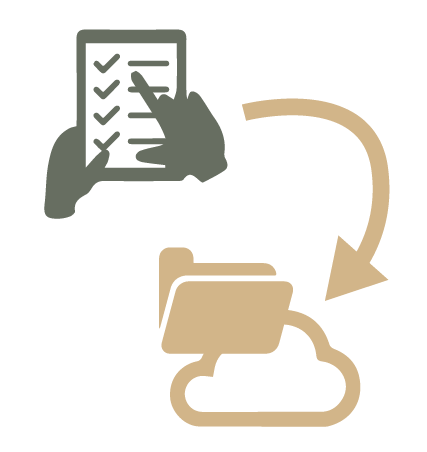

STEP 2. BIM OBJECT

GENERATION.

Based on existing BIM model information from the off site reuse targets, and the downloaded

object information from the reuse database, BIM objects are automatically generated.

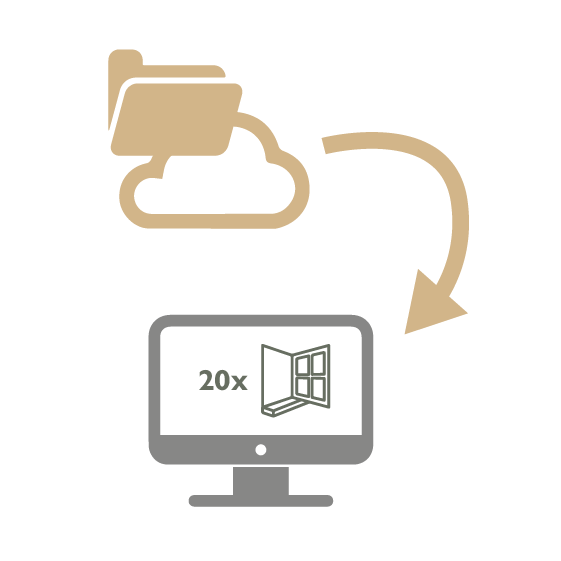

STEP 3. DESIGN PROCESS.

Design, test and iterate your building with the reused BIM

objects by moving them and changing their appearance.

STEP 4. SYNC BACK TO THE REUSE DATABASE.

Book/buy the reused building parts you wish to use by uploading the updated position and owner (saved in the littera) to the reuse database. (API out)

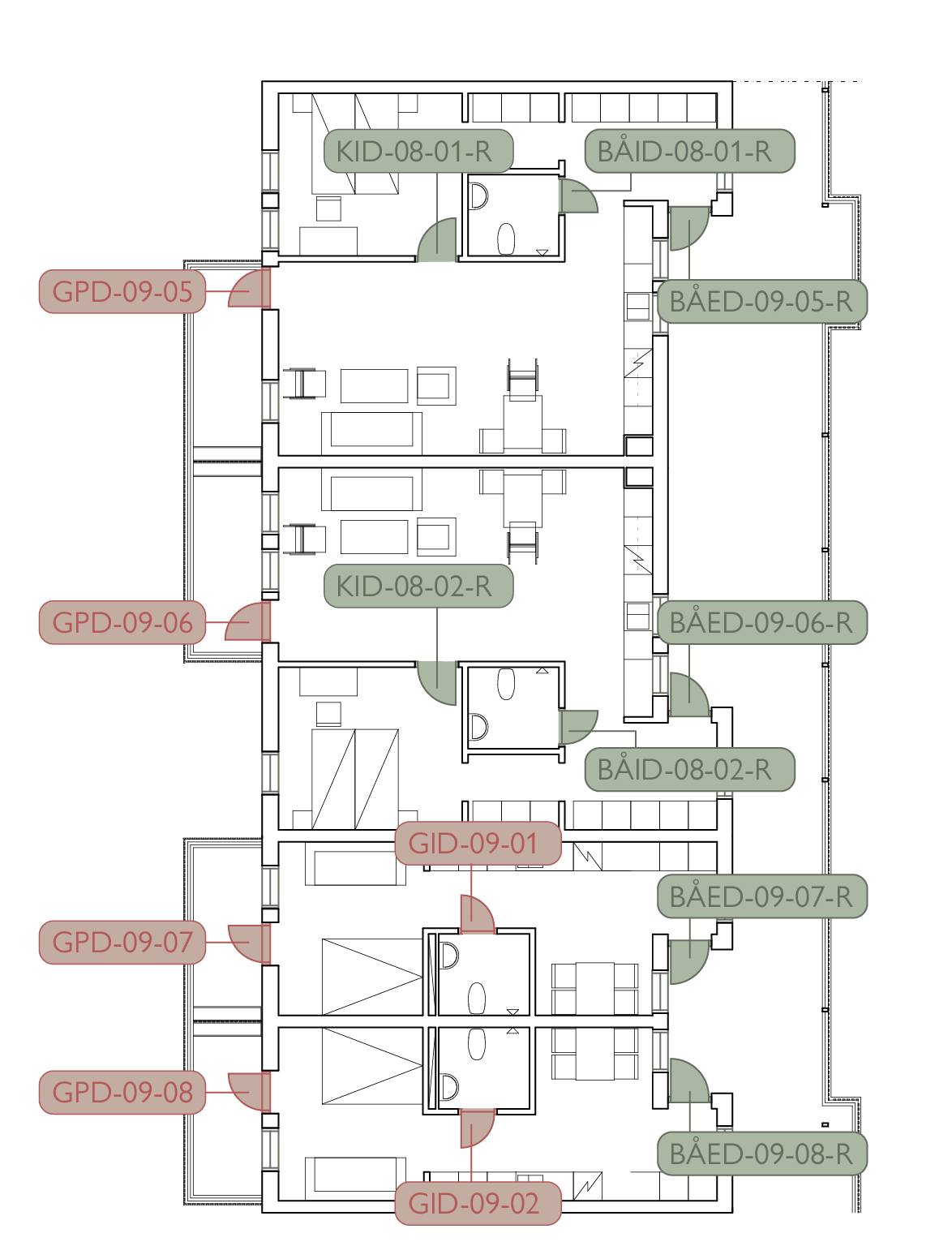

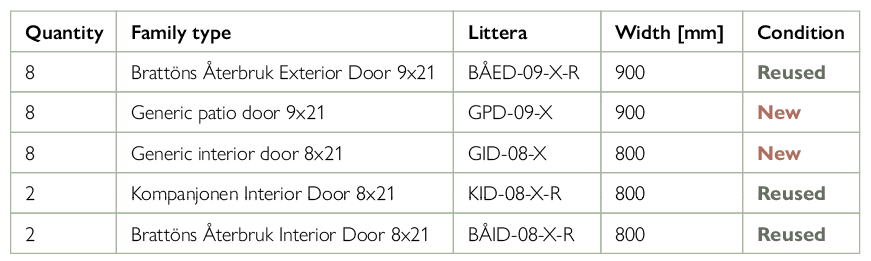

By saving all the reuse information in the BIM model, it can be visible and easily accessed throughout the project. Shared parameters can be used to define if the object is reused or new, and colour-coded accordingly. Unique ID’s from the reuse database can be used to create tags for the reuse BIM objects in the floor plan as well as in schedules.

For more information on how to use BIM to enable visibility and compatibility in the reuse design process, we recommend a browse through our booklet.