2. Mirroring

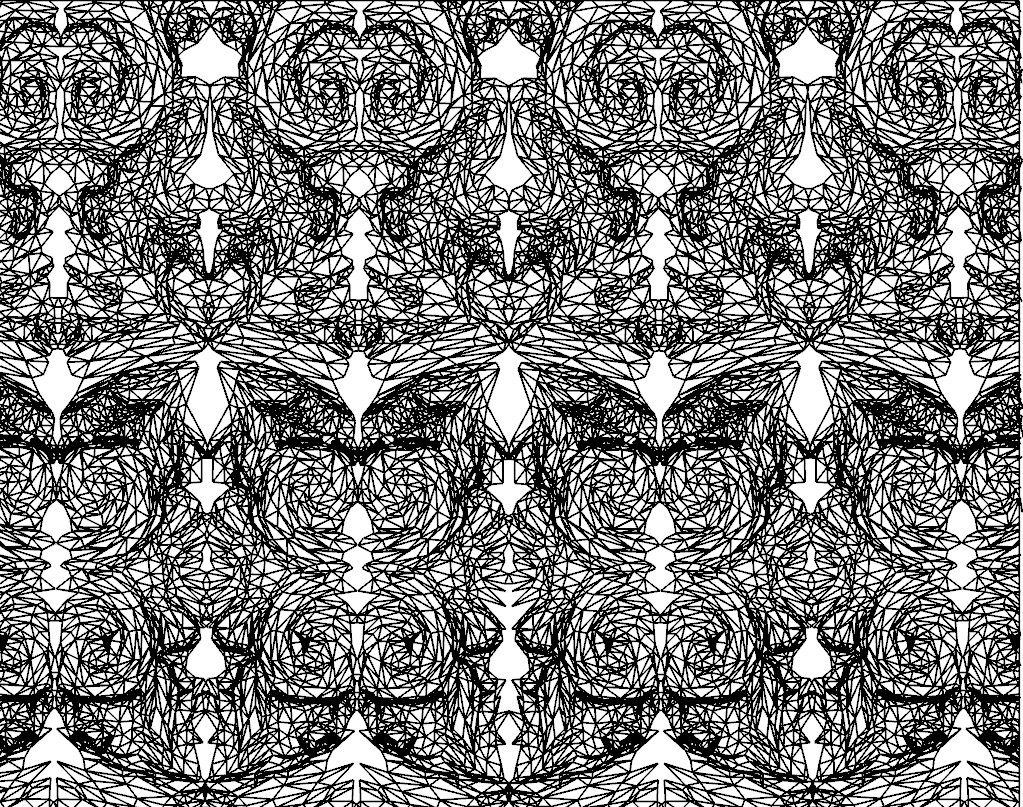

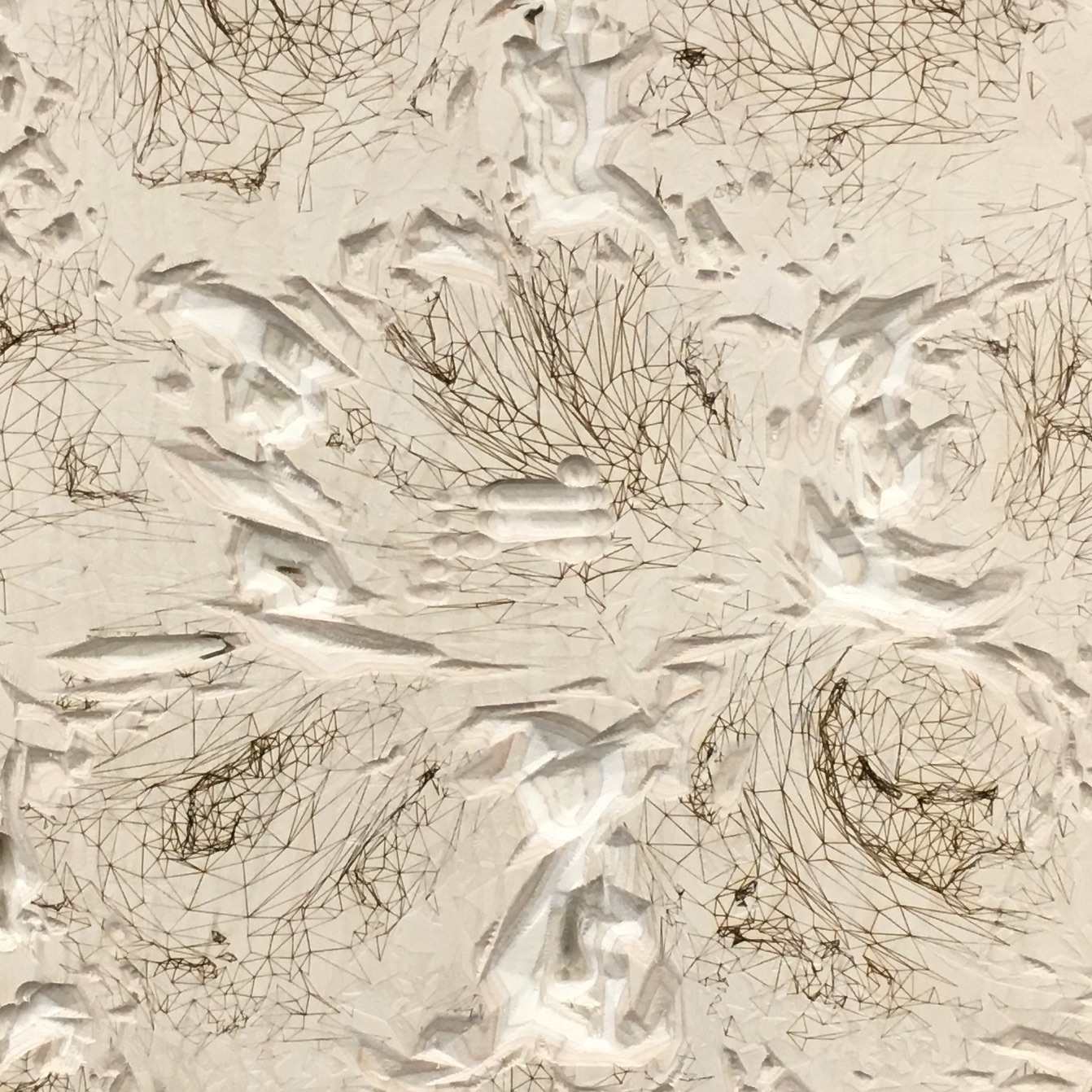

The scanned ornament has symmetrical ambitions, but neither a manual casting or a 3d-scan is usually perfectly symmetrical. What happens if one imposes perfect symmetry on a segment of the scan?

Method

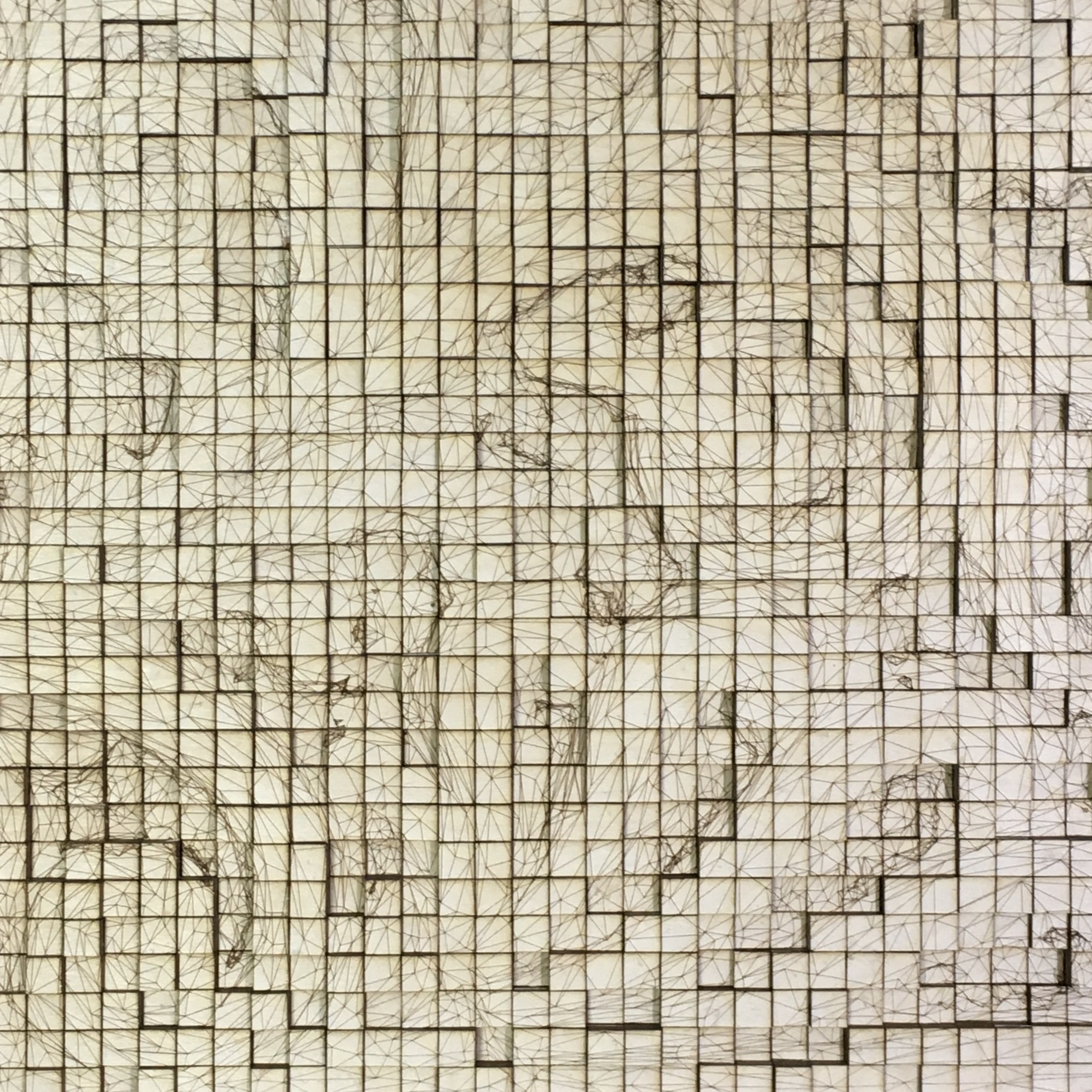

To investigate this, a segment of the scan was mirrored in Rhinoceros using the mirror command and repeating the result in an array. The resulting geometry was projected onto the XY-plane and the pattern was fabricated using the same methods as in Iteration1. This time however, the laser cutter was also used to create perforations in the plywood sheet. The gaps created between the mirrored parts of the mesh was chosen as the parts to be completely cut out.

Result and discussion

In the physical model, the digital expression becomes strong due to the precision of the laser cutter. This time, the symmetry of the lines is close to perfect. However, something that is difficult to control with the laser is the browning of the edges where it cuts through. These occur more or less sporadically and adds a level of uncertainty to the piece. Furthermore, if the plywood is not perfectly flat, the laser can fail in cutting all the way through. This could also be used as a way of accentuating the differences between a perfect digital model and a physical piece. In this iteration, the 3-dimensional expression of the lines is not as prominent. Perhaps due to the segment of the scan that was chosen for the mirroring. But also perhaps due to the perforations putting emphasis on the 2-dimensional nature of the thin plywood sheet.